Common Questions:

What are the advantages of using our SHER-WOOD® Hi-Bild™ Precat Lacquer?

A few of the advantages of SHER-WOOD® Hi-Bild™ Precat Lacquer include:

20% higher volume solids than traditional precat lacquers

Meets KCMA specifications as a self-sealing system

Is fast drying for sanding and packing

Contains UV absorber (see below for more information)

What are some advantages of adding an ultraviolet (UV) finish to a project?

Adding a UV finish allows the wood to last longer, even against high traffic areas. It offers a durable solution that reduces discoloration in order to keep your space looking new.

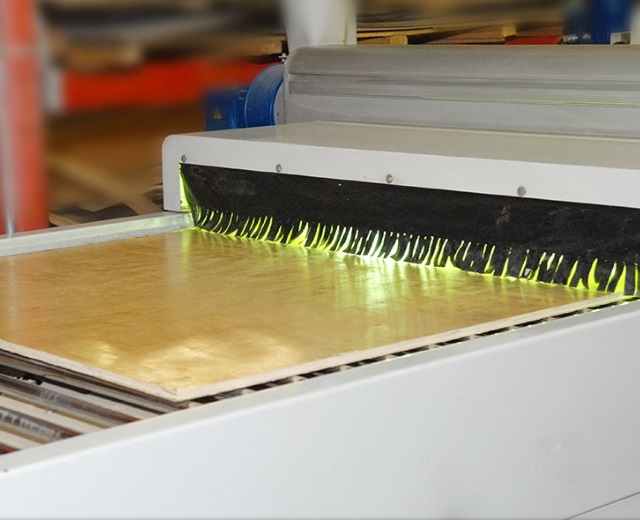

How is UV coating applied to panels, beams, and trims?

The two methods for applying UV coating is by hand or using a machine. First, the lacquer must be catalyzed before application. The benefit of using the UV coating is it offers a versatile application process, including conventional, airless, air-assisted airless spray, or HVLP.

See the download for specifics. (PDF Download)

What projects should use UV coating?

Since the UV coating is designed to withstand discoloration due to increased light exposure, it is ideal for spaces that experience a lot of sunlight.

How long does the SHER-WOOD® Hi-Bild™ Precat Lacquer take to dry?

One benefit of the SHER-WOOD® Hi-Bild™ Precat Lacquer is the fast drying process, see below for the breakdown:

To Touch: 10 – 15 minutes

To Handle: 15 – 20 minutes

To Sand: 30 – 45 minutes

To Recoat/Topcoat: 30 – 45 minutes

To Pack: 8 hour minimum

Force Dry: 5 – 10 minutes at 110 -140°F, then air dry 1hour minimum to pack

Finishing

5th Wall Designs, LLC provides both stained and clear coat finishes (Interior and exterior) to provide the look you want to achieve. If a stain is required a sample(s) will be sent for your approval prior to finishing. All products are finalized with a pre-catalyzed clear laquer. Click the PDF to see our standard clear finish.

Additional specifications

- →Ultraviolet Cured Wood Finishes

- →Pre-Catalyzed Conversion Varnishes and Polyurethanes

- →Durable Exterior Finishes

- →Fire Rated Coating

Storage Temperature

All finished products from 5th Wall Designs should be stored in temperatures ranging from 55 – 85 degrees farenheit with humidity levels between 30-50%.